Efficiency meets Speed.

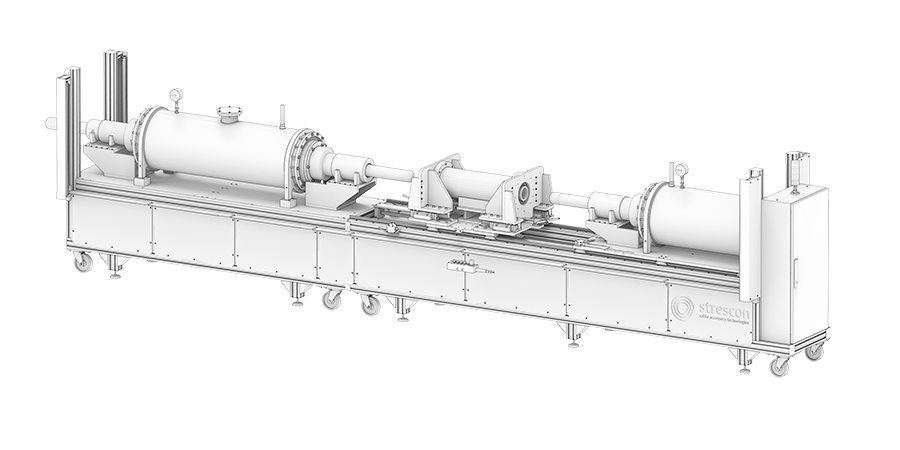

Routine testing has a significant impact on your overall product costs, as preparation, installation and electrical connection of the test objects is very time-consuming. At strescon we have focused on solving this problem, we are specialized in the development and construction of smart and highly efficient routine test equipment that allows you to save valuable time and costs.

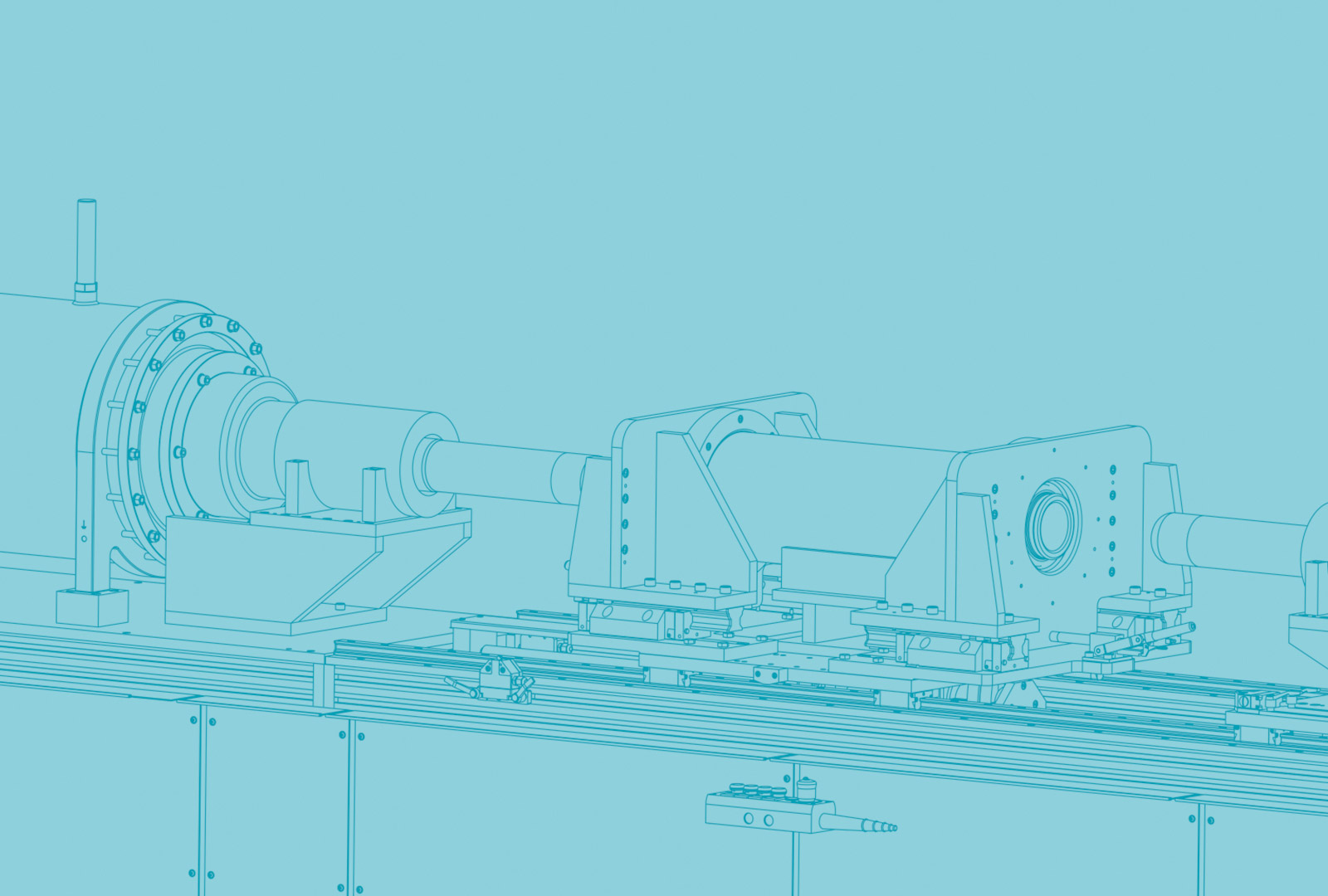

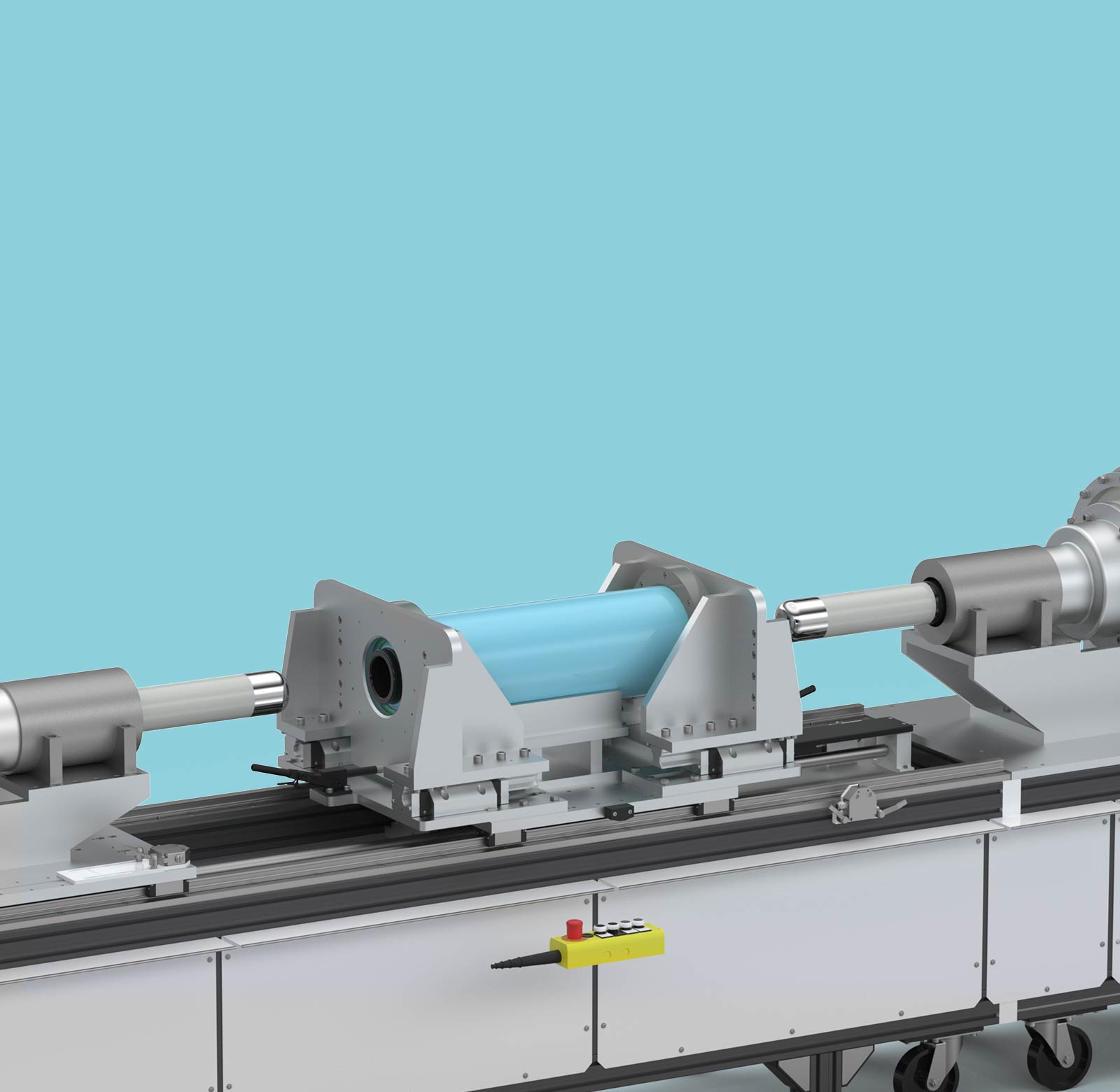

Test setups

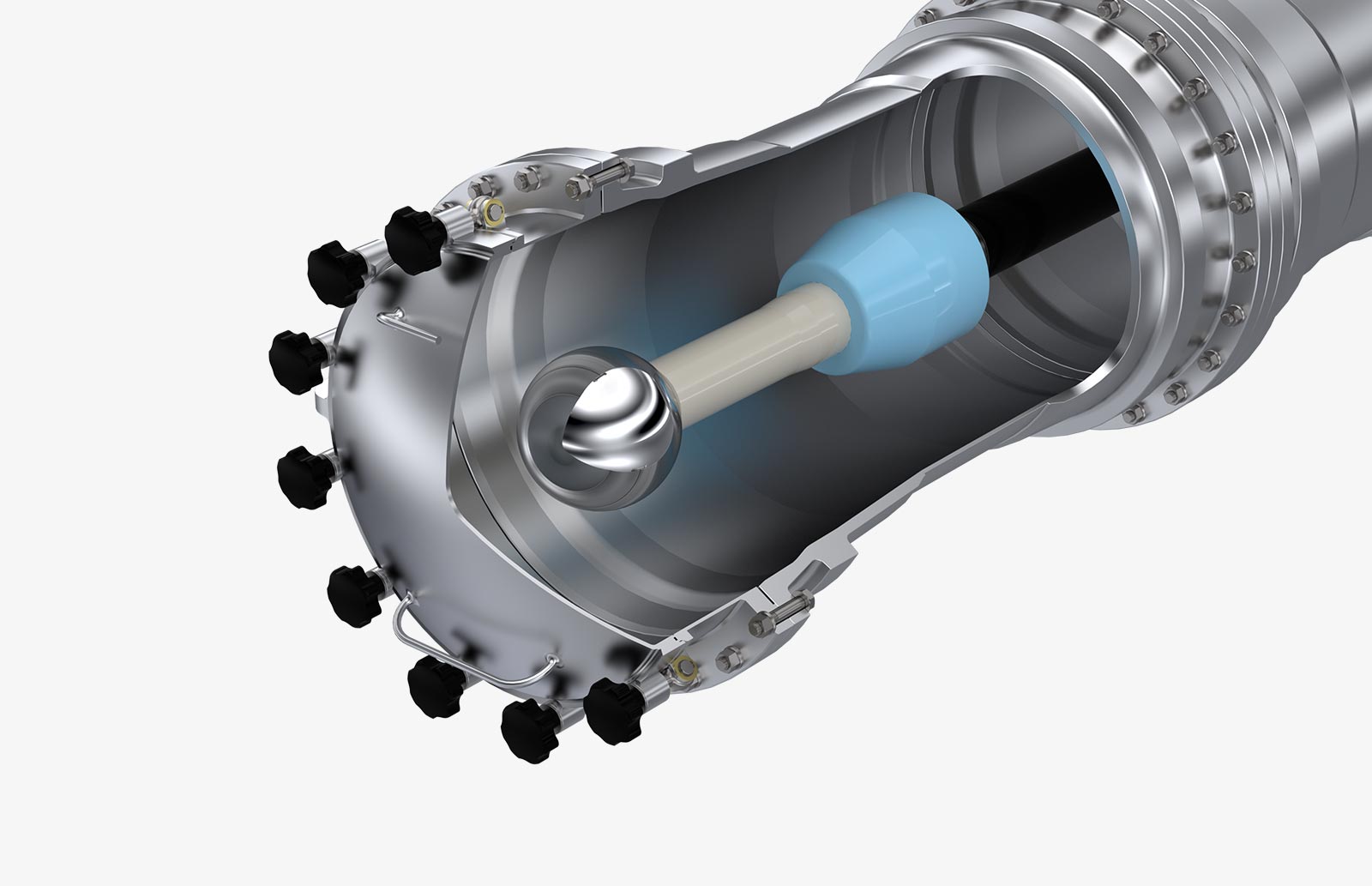

We offer solutions for testing all common types of cable accessories according to the relevant international standards IEC 60840, IEC 62067 and IEC 62271-209. Test rigs for shielded HV-labs as well as fully encapsulated test equipment – We design tailor made testing solutions according to your requirements.

Customized

Your way to your tailor made test equipment.